Houston Heights Metallurgical Testing Services

WH Labs provides extensive metallurgical testing services in Houston Heights, TX and all surrounding areas to address the most challenging material characterization needs across industries. Our holistic approach combines microstructural analysis via SEM and X-ray diffraction with rigorous mechanical testing protocols that reveal critical performance parameters. When manufacturing processes fail or materials underperform, the root causes often hide in microscopic details that standard testing misses. The consequences of these overlooked factors can be catastrophic and entirely preventable.

Key Points

- WH Labs offers advanced characterization techniques including SEM, X-ray diffraction, and electron backscatter diffraction for comprehensive material analysis.

- PhD-level metallurgists conduct mechanical testing and provide actionable insights to improve manufacturing processes.

- Failure analysis services determine root causes and develop prevention strategies for issues like stress corrosion and fatigue.

- Testing protocols align with ISO 9001, ASTM, ASME, and API standards with a 98% first-time certification success rate.

- State-of-the-art equipment detects low-level impurities and microscopic fractures across aerospace, automotive, and construction industries.

Advanced Testing Methodologies for Material Characterization

When evaluating metallurgical properties, we employ exhaustive testing methodologies that provide precise material characterization across multiple parameters. Our advanced techniques include SEM analysis for microstructural examination, X-ray diffraction to identify crystalline phases, and electron backscatter diffraction for grain orientation mapping.

We’ve optimized our procedures to deliver compositional analyses with accuracy to parts per million using ICP-MS and XRF spectroscopy.

For mechanical property assessment, we utilize tensile, compression, and fatigue testing alongside microhardness mapping to generate comprehensive strength profiles.

We also conduct testing to accurately measure fracture toughness of critical components.

You’re not just receiving data; you’re gaining insights from seasoned metallurgists who understand how these parameters interact. We’ll translate complex results into actionable intelligence for your manufacturing processes, helping you join our community of industry leaders who leverage materials science for competitive advantage.

How Failure Analysis Prevents Manufacturing Disasters

While catastrophic component failures can devastate production lines and compromise product integrity, our forensic metallurgy services identify root causes before they escalate into systematic manufacturing disasters. We employ methodical investigation techniques to uncover failure mechanisms that threaten your operations. As an ISO 9001:2015 accredited independent laboratory, we deliver consistent, high-quality testing results you can trust.

| Failure Mode | Prevention Strategy |

|---|---|

| Stress corrosion | Environmental control protocols |

| Fatigue fracture | Stress redistribution designs |

| Hydrogen embrittlement | Material selection optimization |

| Improper heat treatment | Process validation standards |

| Inclusion contamination | Supply chain qualification |

When you partner with our Houston Heights metallurgical team, you’re not simply receiving test results—you’re gaining actionable intelligence. We translate complex failure mechanisms into practical recommendations that shield your manufacturing processes from recurring issues. Our solutions don’t just solve immediate problems; they establish resilient production systems that maintain quality consistency over time.

Compliance Certification: Meeting Global Industry Standards

Guiding through four major international regulatory frameworks demands metallurgical certification expertise that extends beyond basic testing. At WH Labs, we’ve developed extensive protocols that satisfy ISO 9001, ASTM, ASME, and API standards simultaneously, eliminating redundant testing cycles.

Our certification process integrates material validation with documentation systems that withstand rigorous supply chain audits. We’re particularly adept at reconciling conflicting requirements between European EN standards and North American codes—a common challenge for global manufacturers.

When you partner with us, you’re joining a community of industry leaders who maintain compliance without sacrificing innovation. Our metallurgists don’t just identify conformance gaps; they suggest material modifications that preserve your design intent while meeting regulatory thresholds.

This approach has helped our clients achieve 98% first-time certification success across twenty industrial sectors. Through our comprehensive mechanical testing procedures, we ensure materials meet all safety and performance requirements for critical applications.

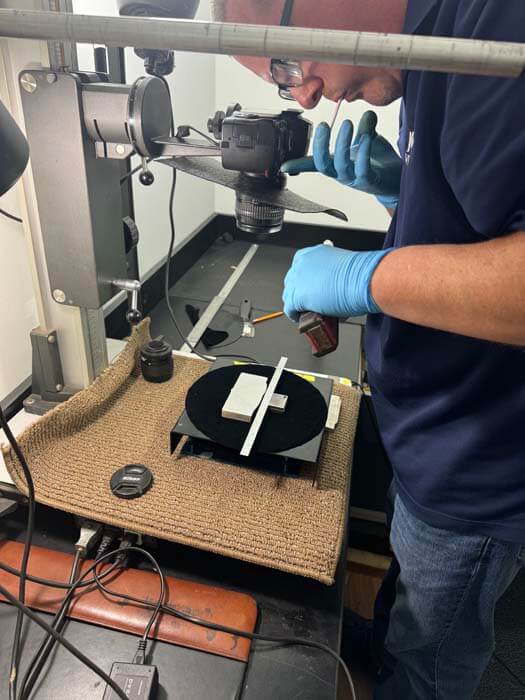

Cutting-Edge Equipment and Expert Metallurgists in Houston Heights

The foundation of our certification success lies in our unique combination of metallurgical expertise and advanced analytical equipment. Our team includes metallurgists with PhDs and decades of industry experience who understand the microstructural properties that determine metal performance.

At WH Labs, we’ve invested in state-of-the-art testing instruments including scanning electron microscopes, X-ray fluorescence spectrometers, and automated hardness testers calibrated to precise tolerances. This equipment allows us to detect impurities down to parts per million and analyze fracture mechanics at the microscopic level.

When you work with us, you’re joining a community of manufacturers who value both technical excellence and practical solutions. We don’t just identify metallurgical issues—we help you understand them and recommend specific process improvements to enhance your product quality.

Our comprehensive mechanical testing services ensure materials meet required specifications for safety and reliability across aerospace, automotive, and construction industries.

Transforming Test Results Into Strategic Business Advantages

Metallurgical testing data becomes truly valuable when translated into actionable business intelligence. At WH Labs, we transform complex analytical results into strategic advantages that impact your bottom line. We’ll help you leverage testing insights to outperform competitors and optimize production processes. Our comprehensive CTOD testing services provide crucial fracture toughness characterization essential for ensuring structural integrity across critical applications.

| Business Impact | Testing Insight | Strategic Advantage |

|---|---|---|

| Cost Reduction | Material Defect Identification | Targeted Process Improvements |

| Quality Assurance | Microstructure Analysis | Enhanced Product Performance |

| Regulatory Compliance | Compositional Verification | Market Access & Certification |

Our metallurgists don’t just deliver data—we provide interpretation that drives decision-making. We’ve structured our reporting systems to highlight critical findings that directly affect your manufacturing efficiency, product durability, and innovation potential. By partnering with us, you’re gaining more than test results; you’re acquiring competitive intelligence that positions your team for success.

Areas We Serve

We’ve established WH Labs as your definitive metallurgical testing partner in Houston Heights and the whole state of Texas with our mobile team, offering microstructural characterization, mechanical testing, and compositional analysis with unmatched precision. Our failure analysis protocols identify root causes that prevent costly manufacturing failures, while our certification services guarantee compliance with stringent global standards. By translating complex metallurgical data into actionable intelligence, we’re enabling evidence-based decision-making that optimizes material performance and operational efficiency. Contact us to get a free quote for all your metallurgical testing needs.

- Bellaire

- Jersey Village

- Spring Valley Village

- Aldine, TX

- South Houston

- Harris County

- La Porte

- Pasadena

- West University Place

- Jacinto City

- Bayport Industrial District

Frequently Asked Questions

What Is the Typical Turnaround Time for Standard Metallurgical Tests?

We deliver most standard metallurgical test results within 5-7 business days. For urgent requirements, we offer expedited services at additional cost, reducing turnaround to 2-3 days.

Do You Offer On-Site Testing Services for Large Equipment?

Yes, we offer on-site metallurgical testing for large equipment. Our mobile units deploy specialized technicians with portable analytical tools to conduct thorough evaluations where dismantling or transport isn’t feasible.

How Are Samples Handled During the Testing Process?

We handle samples with strict chain-of-custody protocols, using specialized containers and unique identifiers. During testing, we maintain temperature control and prevent cross-contamination through our ISO-certified handling procedures you can trust.

What Are Your Laboratory Accreditation and Certification Credentials?

We’re accredited by ISO 17025 and certified by NADCAP for metallurgical testing. Our credentials meet aerospace, defense, and automotive industry standards, ensuring your samples receive globally recognized quality analysis.

Can You Test Custom Alloys or Proprietary Material Compositions?

We specialize in analyzing custom alloys and proprietary compositions using our advanced spectrometry services. We’ll maintain strict confidentiality protocols while providing extensive characterization of your unique material formulations.