Intergranular Corrosion Testing: WH Labs

WH Labs uses intergranular corrosion testing to assess the vulnerability of materials like stainless steel and nickel-based alloys to corrosion along their grain boundaries. These tests are important for ensuring the safety and reliability of materials in various industries. The Copper Sulfate – Sulfuric Acid Technique and the Huey Test are among the methods used to evaluate this susceptibility. By understanding the factors that influence intergranular corrosion, such as solution concentration and material composition, we can better interpret test results and prevent material failure.

Key Points

- Intergranular corrosion testing assesses the vulnerability of materials, such as stainless steel, nickel-based alloys, aluminum alloys, magnesium alloys, and molybdenum-containing austenitic stainless steel.

- The Oxalic Acid Test is a rapid screening method for detecting susceptibility in metals with chromium carbide precipitates.

- The Strauss Test detects intergranular corrosion in high chromium carbide areas by boiling specimens in a Copper Sulfate – Sulfuric Acid solution for 15 hours.

- Key factors influencing IGC tests include solution concentration, material composition, surface preparation, and stress conditions.

- Preventive measures for intergranular corrosion include using low-carbon alloys, incorporating titanium or niobium, and applying solution-annealing.

Intergranular Corrosion Testing Methods

Intergranular corrosion testing covers a variety of methods tailored to evaluate the vulnerability of different materials to this form of localized erosion. We primarily focus on several key methods: the Copper Sulfate – Sulfuric Acid Technique, Nitric Acid Technique, and Sulfuric Acid – Iron Sulfate Technique. These methods are especially beneficial for assessing the intergranular erosion vulnerability of stainless steel, nickel-based alloys, aluminum alloys, magnesium alloys, and molybdenum-containing austenitic stainless steel. Properly selecting and preparing specimens is vital to ensuring accuracy in these tests.

Our testing services are extensive and adaptable, allowing us to customize tests to meet specific needs. This includes erosion inhibitor testing, crevice erosion testing, electrochemical erosion testing, galvanic erosion testing, and high-pressure high-temperature (HPHT) erosion testing. Our expertise extends to investigating the vulnerability of various materials to intergranular erosion, including tin-added austenitic stainless steel, metastable austenitic Cr-Mn-Ni-N-Cu steel, and stabilized ultra-pure 430LX ferritic stainless steel.

We understand the significance of precise testing in determining the resistance of materials to intergranular erosion. Our methods guarantee that the materials used in various industries are safe and reliable, preventing unforeseen failures due to erosion.

Oxalic Acid Test Procedure

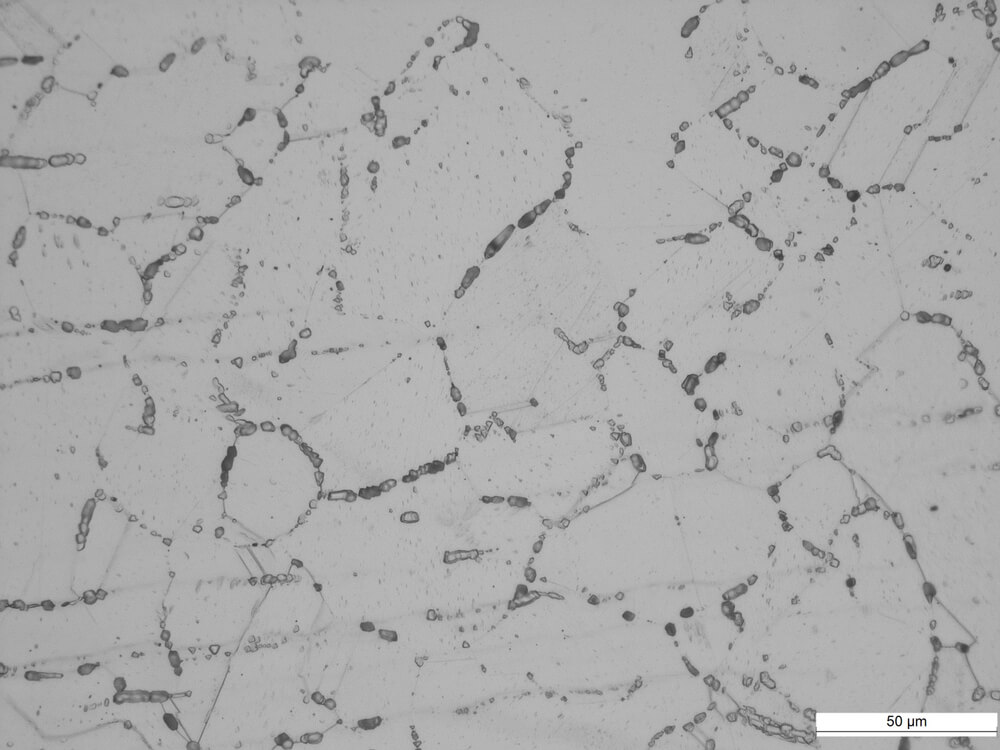

The Oxalic Acid Test Procedure plays a key role in evaluating the vulnerability of certain materials to intergranular corrosion. We use this rapid screening method to detect susceptibility in metals associated with chromium carbide precipitates. The test helps us quickly identify materials prone to this type of corrosion, classifying samples as either Acceptable or Suspect based on the presence of carbide precipitation. This procedure is part of the ASTM A262 Practice A testing method and is specific to certain material grades.

It’s essential to keep in mind that the Oxalic Acid Test isn’t meant for quantifying corrosion levels but serves as an initial indicator of susceptibility. By applying oxalic acid to the metal surface, we can observe the reaction and determine if the material is at risk of intergranular corrosion. Factors like chemical composition and heat treatment can affect the accuracy of this test, making it crucial to take these variables into account.

The test’s specificity and speed make it a valuable tool in our assessment process, allowing us to take prompt action to mitigate potential corrosion issues.

Strauss Test for Corrosion

We use the Strauss Test, a method within ASTM A262, to specifically detect intergranular corrosion in areas with high chromium carbide formations. This test is essential for evaluating the susceptibility of materials to corrosion in these specific conditions. The procedure involves boiling the specimen in a Copper Sulfate – Sulfuric Acid solution, which aids in identifying the extent of intergranular corrosion. Proper sample preparation and mounting are vital to prevent inaccurate results during this test.

The Strauss Test is unique in its focus on high chromium carbide areas and isn’t effective for examining other causes of intergranular attack. This specificity makes it a valuable tool for materials that are prone to corrosion in these conditions.

The test typically lasts for 15 hours, after which the specimen undergoes a bend test and visual examination. The outcome of this evaluation determines whether the specimen passes or fails, providing a clear indication of its vulnerability to intergranular corrosion. This method guarantees that materials susceptible to corrosion in high chromium carbide areas are identified and appropriate measures can be taken.

Huey Test Explanation

Five distinct intervals of 48 hours each define the Huey Test, part of ASTM A262 Practice C, where specimens are immersed in a nitric acid solution to evaluate their susceptibility to intergranular corrosion. We conduct this test to appraise the material’s resistance to intergranular attack, particularly in areas with high chromium carbide formations. By measuring mass loss at each interval, we can determine the extent of corrosion in specific microstructural regions, aiding in evaluating the material’s overall susceptibility to intergranular attack.

The Huey Test is preferred for identifying areas with high chromium carbide formations and evaluating the potential for intergranular corrosion in austenitic stainless steels. This test helps us understand how materials perform in strongly oxidizing environments, like nitric acid. By analyzing the corrosion susceptibility of materials, we can detect sensitization and carbide precipitation, which are critical factors in determining the material’s resistance to intergranular attack.

Streicher Test Method

Building on our understanding of the Huey Test’s effectiveness in evaluating intergranular corrosion susceptibility in austenitic stainless steels, particularly in areas with high chromium carbide formations, we move on to another significant method within ASTM A262: the Streicher Test Method.

The Streicher Test, part of ASTM A262 Practice B, involves boiling specimens in a Ferric Sulfate – Sulfuric Acid solution to assess intergranular corrosion susceptibility in stainless steel and nickel alloys. The test measures the mass loss of the specimen during the test, which can range from 24 to 120 hours. This method helps evaluate the material’s resistance to intergranular attack by examining the extent of corrosion.

Key Points of the Streicher Test Method:

- Intergranular Corrosion Evaluation: The Streicher Test specifically targets the susceptibility of materials to intergranular corrosion.

- Ferric Sulfate – Sulfuric Acid Solution: The test involves boiling specimens in this solution to induce corrosive conditions.

- Mass Loss Measurement: The level of corrosion is determined by measuring the mass loss of the specimen during the test.

- Variable Test Duration: The test can range from 24 to 120 hours, depending on the specific requirements.

The Streicher Test is vital for ensuring that materials are properly processed to resist intergranular corrosion, especially in applications where such susceptibility could lead to material failure.

Copper Sulfate Test Details

The Copper Sulfate Test, outlined in ASTM A262, is a critical method for evaluating the susceptibility of stainless steel and nickel alloys to intergranular corrosion. We use this test to assess the material’s resistance to intergranular attack by exposing specimens to a boiling copper sulfate-sulfuric acid solution. The test is particularly effective for determining susceptibility to intergranular attack in low carbon steels.

The Copper Sulfate Test involves boiling the specimen in the copper sulfate-sulfuric acid solution for 15 hours. After exposure, we perform a visual examination of the bent specimen to determine pass or fail. The test is based on the presence or absence of intergranular cracking or crazing, which indicates susceptibility to intergranular corrosion.

Factors Affecting IGC Tests

When evaluating the susceptibility of stainless steel and nickel alloys to intergranular corrosion using the Copper Sulfate Test, it becomes clear that several factors can greatly influence the test results. Test conditions such as duration and environment significantly impact the severity of intergranular corrosion in materials. For instance, the presence of hydrogen sulfide in sour environments can worsen IGC and other forms of corrosion.

Key Factors Influencing IGC Tests:

- Solution Concentration: Higher concentrations can increase the corrosive potential, leading to more severe IGC.

- Material Composition: The presence of certain elements like chromium and nickel can impact a material’s resistance to IGC.

- Surface Preparation: The way a material’s surface is readied can affect its susceptibility to corrosion.

- Stress Conditions: Stress during testing can raise the stress corrosion cracking coefficient, making materials more prone to sudden failures.

Understanding these factors is important for conducting accurate and reliable IGC tests. By considering these influences, we can better predict and mitigate the risks of intergranular corrosion in various materials and environments.

Interpreting IGC Test Results

To accurately interpret IGC test results, we need to take into account the specific criteria for each test method, as these criteria help determine the material’s susceptibility to intergranular corrosion. Factors such as carbon content, chromium distribution, grain size, heat treatment, and processing history greatly influence the test outcomes.

Result Interpretation Factors

Evaluating IGC test results effectively necessitates careful examination of multiple factors, such as carbon content, chromium distribution, grain size, heat treatment, and processing history. These elements can greatly impact the interpretation of test results, and it’s vital to align our evaluation with accepted criteria for specific testing methods.

To ensure precise assessment, we need to take into account the following key factors:

- Carbon content: Elevated carbon levels can heighten susceptibility to intergranular corrosion.

- Chromium distribution: Irregular chromium distribution can result in weakened grain boundaries.

- Grain size: Larger grain dimensions can heighten the risk of intergranular corrosion.

- Heat treatment and processing history: Improper heat treatment or processing can sensitize materials to intergranular corrosion.

Analyzing Test Criteria

Intergranular corrosion test results demand meticulous analysis to accurately determine the susceptibility of metals to this type of corrosion. When we scrutinize test criteria for intergranular corrosion tests, we must consider several key factors. These include the carbon content, chromium distribution, grain size, heat treatment, and processing history of the material.

Each testing method has its own set of requirements, such as agitation, specific solution concentrations, and consideration of material properties. The costs of these tests can vary based on the complexity of the material being tested and the demands of the specific test method.

In the context of austenitic stainless steels, tests like the Huey test, Strauss test, and oxalic acid etching test are commonly used to assess susceptibility to intergranular attack. These tests help reveal reductions in mechanical strength, ductility, and overall corrosion resistance of materials.

Preventing Intergranular Corrosion

Preventing intergranular corrosion requires careful consideration of the alloy composition and heat treatment history. We need to understand how different factors contribute to this type of corrosion to effectively mitigate its risks.

To prevent intergranular corrosion, we can take several key steps:

- Use Low-Carbon Alloys: Selecting materials with low carbon content significantly reduces the risk of intergranular corrosion. Alloys with less than 0.05% carbon are generally more resistant.

- Add Titanium or Niobium: Incorporating elements like titanium or niobium can help stabilize the alloy and prevent chromium carbide precipitation, a common cause of intergranular corrosion.

- Solution-Annealing: Heating austenitic stainless steel to a high temperature and then quenching it can reduce susceptibility to intergranular corrosion by ensuring a uniform distribution of chromium.

- Material Selection: Choosing the right material based on its intended application and environment is essential. Understanding the alloy’s composition and potential for sensitization helps in minimizing the risk of intergranular corrosion.

Material Susceptibility to IGC

As we consider the susceptibility of materials to intergranular corrosion (IGC), it’s imperative that we comprehend the specific risk factors linked with different materials.

We must analyze the composition and microstructure of materials like stainless steel, nickel-based alloys, aluminum alloys, magnesium alloys, and molybdenum-containing austenitic stainless steels to ascertain their vulnerability to IGC.

IGC Risk Factors

Material susceptibility to intergranular corrosion (IGC) is influenced by a variety of factors, each playing an important role in determining the risk of this corrosive process. As we explore the specifics of IGC risk factors, it becomes clear that understanding these elements is essential for evaluating the risk of intergranular corrosion in various materials.

Key Factors Influencing IGC Susceptibility

- Carbon Content: High carbon content can lead to chromium carbide precipitation, increasing susceptibility to IGC.

- Sensitization: Austenitic stainless steels are particularly prone to IGC due to sensitization, which results in chromium depletion at grain boundaries.

- Surface Preparation and Processing History: The way a material is processed and its surface prepared can have a significant impact on its vulnerability to IGC.

- Alloy Composition: Nickel-based alloys, for instance, may exhibit intergranular attack if sensitized or exposed to corrosive environments.

Understanding the material’s behavior in specific environments is vital for evaluating the risk of intergranular corrosion. By considering these factors, we can better predict and mitigate the risks associated with IGC.

Material Selection Strategies

To effectively mitigate the risk of intergranular corrosion (IGC), we need to focus on selecting materials that are inherently less prone to this corrosive process. This involves choosing low-carbon alloys or those with added titanium or niobium, which can greatly reduce the susceptibility to carbide precipitation and subsequent IGC.

Additionally, solution-annealing austenitic stainless steel is a vital step in minimizing the risk of IGC, as it helps to dissolve any precipitated carbides and restore the chromium-depleted zones near the grain boundaries.

The composition and processing history of materials play a pivotal role in determining their susceptibility to IGC. Hence, understanding the alloy’s heat treatment and sensitization potential is key in minimizing the risk of IGC. By selecting materials that are resistant to IGC and ensuring proper heat treatment, we can markedly reduce the likelihood of intergranular corrosion and maintain the integrity of components in corrosive environments.

Proper material selection is crucial in this regard, as it directly impacts the longevity and reliability of the equipment.

Frequently Asked Questions

What Is an Intergranular Corrosion Test?

We use intergranular corrosion tests to assess a material’s susceptibility to corrosion along grain boundaries. These tests help us identify materials prone to intergranular corrosion, ensuring we select the right materials to prevent corrosion-related failures.

What Is Galvanic Corrosion Test?

We use galvanic corrosion tests to assess the susceptibility of metals in contact with each other in an electrolyte. These tests help us identify materials that may experience accelerated corrosion, ensuring we select compatible materials and protective measures.

How Do You Identify Intergranular Corrosion?

We identify intergranular corrosion through specific testing methods like ASTM A262 practices, exposing specimens to corrosive solutions. Common tests include the Oxalic Acid Test, Huey Test, Streicher Test, and Strauss Test to determine susceptibility to intergranular attack.

What Materials Are IGC Tested On?

We test materials like stainless steel, nickel-based alloys, aluminum alloys, magnesium alloys, and molybdenum-containing austenitic stainless steels for intergranular corrosion. These materials are prone to IGC due to their microstructures and compositions.

The Takeaway

We conclude that intergranular corrosion testing methods, such as the Oxalic Acid Test, Strauss Test, Huey Test, and Streicher Test, are essential for evaluating the susceptibility of materials like stainless steel and nickel-based alloys to corrosion along grain boundaries. These tests help guarantee material safety and reliability in various industries. Accurate testing and analysis are vital to prevent material failure, and understanding factors like solution concentration and material composition is crucial to interpreting test results effectively.