WH Labs: Trusted Metallurgical Testing Experts

As an industrial site manager, you know the cost of downtime and the importance of reliable equipment. At WH Labs in Houston, Texas, our mission is to help you keep your operations running safely by uncovering what’s happening inside your metals. We specialize in metallurgical testing, weld inspection, and failure analysis to solve tough materials problems (WH Labs – Metallurgical Testing and More).

Company Background and Quality Commitment

WH Labs (White House Laboratories) has been serving the industry for over three decades (Metallurgical Testing Lab – WH Labs). Since the 1990s, our independent lab has built a reputation for thorough testing and practical solutions. We operate under rigorous quality standards – we’re an ISO 9001:2015 accredited facility with ASME U and U2 certifications for pressure components (Company Profile – WH Labs). These credentials, along with specialized accreditations like Nadcap (for aerospace) and PJLA (ISO/IEC 17025) lab accreditation, underscore our commitment to excellence and reliable results (Metallurgical Testing Lab – WH Labs). In short, we’ve invested in the people and certifications that ensure you can trust our findings every time.

Comprehensive Metallurgical Testing Services

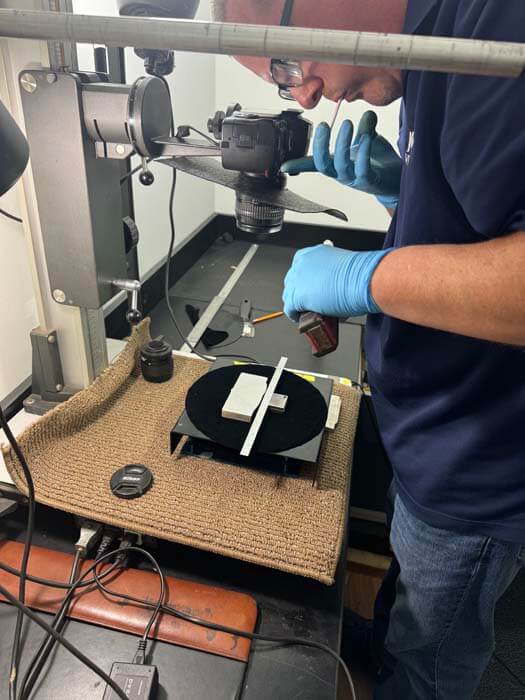

(Metallurgical Testing – WH Labs) Technicians at WH Labs use heavy-duty testing machines to evaluate the strength of metal samples. We offer a one-stop shop for a wide range of metallurgical tests, meaning you don’t have to juggle multiple labs to get answers. Our Houston laboratory is equipped with advanced instruments (from Instron universal testers to spectrometers and scanning electron microscopes) that let us examine materials from the macro scale down to the microscopic level. This comprehensive approach ensures we can characterize your material’s performance, composition, and integrity under one roof.

Some of our core testing capabilities include:

- Mechanical Testing: Measuring material strength and toughness with tensile pulls, bend tests, and impact tests (Charpy/Izod). We also perform extensive hardness testing (Rockwell, Brinell, microhardness, and portable hardness) to verify a component’s resistance to wear (Metallurgical Testing – WH Labs). These tests confirm if your metal parts can withstand the stresses of real-world operation.

- Chemical Analysis: Identifying alloy composition and grade to make sure you got the material you specified. Using techniques like optical emission spectrometry and Positive Material Identification (PMI), we determine the exact chemical makeup of ferrous and non-ferrous alloys (Metallurgical Testing – WH Labs). This helps catch material mix-ups and ensures compliance with required specs.

- Microstructure Examination: Using metallography and microscopy to inspect the internal structure of metals. We prepare samples (even on-site, if needed) to analyze grain size, check heat treatment quality, and detect any micro-cracks or weld defects (Metallurgical Testing – WH Labs). For example, our team can reveal if a weld’s heat-affected zone has the proper grain structure or if a hardened steel has the expected martensitic microstructure.

- Corrosion and Specialty Testing: Evaluating how materials hold up in harsh environments. We perform corrosion evaluations and coating tests – from exposing samples to simulated chemical environments to checking protective coating adhesion (Metallurgical Testing – WH Labs). If your equipment operates in corrosive conditions (like offshore or chemical plants), we can test and advise how the metal will fare over time. We also offer specialized tests such as ferrite content determination in stainless steels and fracture mode analysis to understand how a part failed.

By covering mechanical properties, chemistry, microstructure, and corrosion behavior, WH Labs provides a 360° view of your material’s health. In practice, this means whether you’re verifying a weld procedure or investigating why a bolt snapped, we have the tools and expertise to get you answers.

Industries We Serve

Our lab’s experience spans a broad range of industries, reflecting the diverse Houston economy. We regularly work with clients in oil and gas, petrochemical refining, power generation, manufacturing, and even aerospace and automotive sectors (Metallurgical Testing Lab – WH Labs). Whether it’s a drill bit from an oil rig or a turbine blade from a power plant, we’ve likely seen something similar come through our doors. Our client list includes major energy companies, petrochemical firms, metal fabricators, and equipment manufacturers – names like ExxonMobil, Shell, Schlumberger, and Halliburton, to name a few (Company Profile – WH Labs). We’ve even assisted government agencies on infrastructure projects (for example, the Texas Dept. of Transportation has trusted us for materials testing (Company Profile – WH Labs)). This wide industry exposure means we understand the real-world conditions your components face and the standards they must meet. From rugged pipeline steels to high-temperature alloys for aerospace, our team is familiar with the materials critical to your business.

What Sets Us Apart

At WH Labs, we pride ourselves on being more than just a test report mill – we’re your problem-solving partner. Fast turnaround is one way we stand out: we know you can’t afford to wait weeks for results, so our lab is optimized to deliver prompt, precise reports. In fact, we often email you the test results as soon as they’re ready, because timely information is crucial for your decision-making (Metallurgical Testing Lab – WH Labs).

Another hallmark of our service is the expert guidance that comes with the data. When things go wrong with a valve, weld, or piece of equipment, our experts help figure out why and what to do next. We can perform a full failure analysis – from a simple hardness check to an exhaustive investigation – and then advise you on whether you can continue running, need a repair, or must replace the component (WH Labs – Metallurgical Testing and More). This “run, repair or replace” advice (WH Labs – Metallurgical Testing and More) is something our clients value because it directly informs maintenance and safety decisions on the ground.

We also offer on-site support for those times you can’t send a sample to the lab. Our team can come to your facility for services like Field Metallographic Replication – essentially taking a portable snapshot of a material’s microstructure in the field without damaging your equipment (Metallurgical Testing Lab – WH Labs). This means if you have a giant piece of machinery or a fixed installation (like a refinery vessel) that needs evaluation, we can examine it right on-site. By combining field expertise with our lab analysis, we make sure you get actionable answers no matter where the problem is.

Lastly, our people make the difference. We’ve assembled a skilled team of metallurgists and welding inspectors who have seen it all, and we maintain a friendly, down-to-earth approach. We understand the pressures you face, and we speak your language. In short, we treat your problem as if it were our own, focusing on practical solutions, not just raw data.

Our Credentials and Reliability

Quality and safety are the backbone of everything we do. Along with our ISO 9001:2015 certification and ASME stamps, we adhere to stringent industry standards like ASTM and API for testing protocols (Metallurgical Testing Lab – WH Labs). Every test is performed following established procedures, so the results hold up to scrutiny. We are proud to hold PJLA accreditation to ISO/IEC 17025, which means our lab’s technical competence is independently audited – you can be confident our measurements are accurate and traceable. For specialized sectors such as aerospace, we’ve gone the extra mile to obtain Nadcap accreditation, demonstrating our capability to meet the strict requirements of aerospace material testing (Metallurgical Testing Lab – WH Labs). All of these credentials boil down to one thing: assurance that when you get a report from WH Labs, it’s going to be right. We stand behind our results, and so do the certification bodies and industry authorities. This reliability is why so many companies trust us with critical testing work year after year.

Partnering for Your Success

At the end of the day, our goal is to give you peace of mind about your metal components. We want you to sleep a little better at night knowing that that repaired pressure vessel has been thoroughly inspected, or that the welds on your structure have been tested and meet code. Our motto, “We specialize in solutions to your problems,” isn’t just a slogan – it’s how we approach every job (WH Labs – Metallurgical Testing and More). From the first phone call to the final report, we strive to make the testing process clear, quick, and useful for you and your team.

(Metallurgical Testing – WH Labs) Fractured metal test specimen examined at WH Labs during a failure analysis. When a part breaks or doesn’t perform as expected, we dig down to the metallurgical root cause. Was it a material defect, the wrong heat treatment, or unforeseen service conditions? Our failure analyses combine all our lab capabilities – microscopic examination of fracture surfaces, hardness testing around the break, chemical analysis of the material, etc. – to reconstruct the story of the failure. We then translate that into practical recommendations for you. Perhaps the analysis shows a need for a different alloy to prevent brittle failure, or maybe just a procedural change in welding to avoid porosity (like in the image above). Whatever the findings, our aim is to help you prevent the problem from recurring and improve your operations.

In summary, WH Labs is here to support Houston’s industrial community with top-notch metallurgical testing services. We’re a local lab with world-class capabilities, and we take pride in being a trusted partner to the folks who keep the gears of industry turning. Whether you have a one-off failure that needs investigation, or you want a reliable lab for routine testing of your welds and materials, we’re ready to help. Feel free to reach out to us – as the general manager, I’d be happy to discuss how our expertise can assist in keeping your site safe, compliant, and efficient. After all, your success is our success, and nothing makes us more proud than seeing our clients confidently push forward, backed by solid data and solutions we’ve provided.