Mechanical Testing to Ensure Material Strength and Toughness

Mechanical testing is the backbone of verifying that metal parts can withstand real-world stresses. Whether you have a steel beam for construction or a critical turbine component, these tests measure how much load, bending, or impact a material can take before it yields or breaks. At WH Labs, we specialize in comprehensive mechanical testing services, from tensile pulls and bend tests to impact and hardness measurements – all aimed at ensuring your metal parts are up to the task. Our laboratory’s reputation as the best and most trusted facility in this field comes from decades of expertise and state-of-the-art equipment, giving you confidence that your materials meet the highest standards of strength and toughness.

The Importance of Mechanical Testing

Imagine the bolts on a pressure vessel or the axle of a heavy truck. How can you be certain they won’t fail under stress? Mechanical testing provides quantitative evidence of a material’s strength, ductility, and toughness. By subjecting material samples to controlled forces, we can simulate real-world conditions in a lab setting. These tests confirm that your metal parts can handle the loads, impacts, and wear they will encounter in operation. In fact, tensile and impact tests were historically developed to prevent catastrophic failures of machines like boilers and bridges by understanding material limits. Today, industries from aerospace to oil & gas rely on mechanical testing data to ensure safety and reliability. In short, mechanical testing matters because it separates materials that merely look strong from those proven to be strong when it counts.

Key Mechanical Tests and What They Reveal

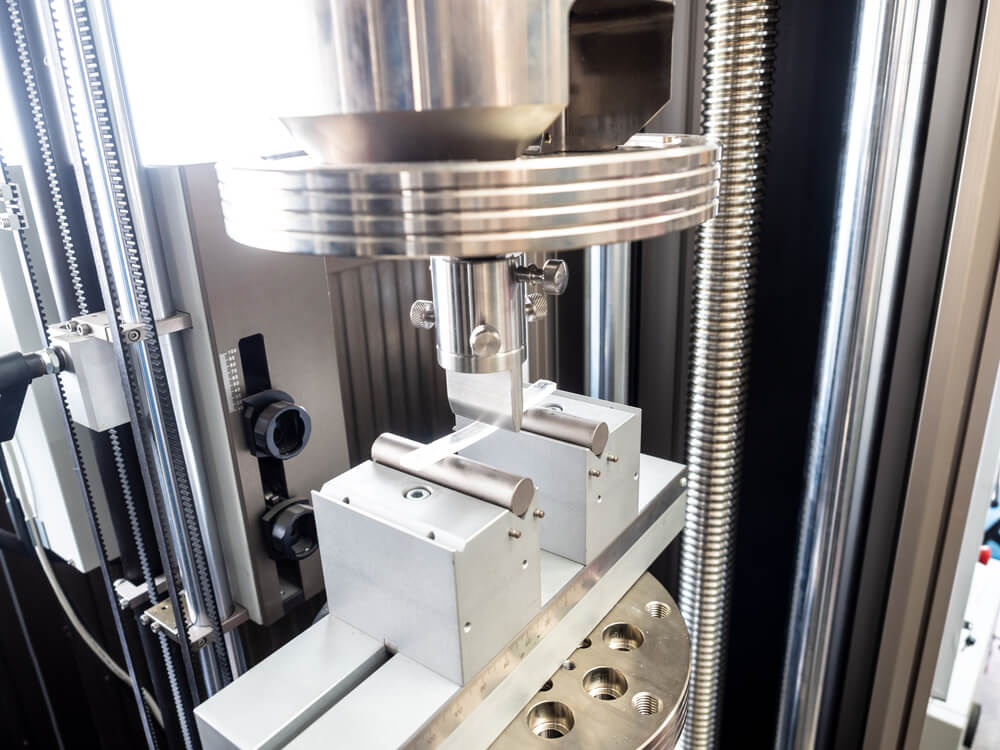

Tensile Testing: Tensile tests measure how a material behaves when pulled apart. A sample (often a dog-bone shaped coupon) is placed in a universal testing machine and stretched until it breaks. This test directly measures properties like ultimate tensile strength, yield strength, and elongation. For example, steel bolts might require a certain tensile strength (the maximum stress before breaking) and elongation percentage (how much they stretch before breaking) to be safe. Tensile results tell us if a metal is strong enough and if it has a ductile “give” or is too brittle. At WH Labs, our technicians carefully follow ASTM standard procedures for tensile testing, ensuring accurate measurements of your material’s load-bearing capacity.

Bend Testing: In bend tests, we bend a material sample (often a coupon or welded joint) to a specified angle to check its ductility and soundness. This is commonly used for weld qualifications – for instance, bending a welded strip to see if the weld cracks or holds together. A successful bend test with no cracks indicates the material (or weld) has good ductility and fusion. WH Labs performs guided bend tests for weld procedure qualifications and material evaluations, helping verify that welded components won’t fail when flexed in service.

Impact Testing (Charpy/Izod): Impact tests measure a material’s toughness – its ability to absorb energy without fracturing. In a Charpy V-notch test, a standardized notched sample is struck by a swinging pendulum hammer, and the energy absorbed in breaking the specimen is recorded in joules. A high-energy absorption means the material is tough and can withstand sudden shocks (it deforms more before breaking), whereas a low value indicates brittleness (it cracks with little energy). This test is crucial for applications like bridge steel in cold climates or pressure vessel materials, where brittle fracture must be avoided. WH Labs conducts both Charpy and Izod impact tests in accordance with ASTM standards (such as ASTM E23 for metals), using calibrated pendulum machines. Our impact testing services can determine if your metal maintains toughness at low temperatures or under dynamic loads – essential for preventing unexpected brittle failures.

Hardness Testing (Rockwell, Brinell, Microhardness, Portable): Hardness tests evaluate a material’s resistance to indentation and wear. These are quick, non-destructive tests that correlate with strength and wear resistance. In the Rockwell hardness test, for example, an indenter is pressed into the material under a standard load and the depth of indentation is measured to give a hardness number. A higher hardness number means the material is harder (resists indentation more) and often indicates greater strength or wear resistance. We offer several hardness testing methods: – Rockwell Hardness: Uses a diamond or ball indenter with a specific major load to give a direct hardness reading (e.g. HRC for steels). This is great for quick checks of metals – for instance, confirming a gear has been properly hardened by heat treatment.

– Brinell Hardness: Involves pressing a hardened steel ball under a heavy load and measuring the impression diameter. Brinell is often used for castings and forgings; it gives an average hardness over a larger area, useful for heterogeneous materials.

– Microhardness (Vickers/Knoop): Uses a very small diamond indenter and microscope measurement, allowing hardness checks on microscopic regions like case hardened surfaces, individual microstructures, or thin coatings. This helps verify if a surface hardening process achieved the desired case depth and hardness.

– Portable Hardness Testing: We can also perform hardness tests in the field using portable devices (like rebound or ultrasonic hardness testers). This is invaluable for testing large equipment or installed components without cutting a sample. For example, WH Labs can bring a portable hardness tester on-site to measure the hardness of pipeline welds or pressure vessel walls as part of maintenance inspections.

Each of these tests provides a piece of the puzzle regarding your material’s fitness for service. For instance, a high hardness often correlates with good wear resistance but could indicate brittleness if not paired with adequate toughness. That’s why a combination of tests – tensile for overall strength, impact for toughness, and hardness for surface strength – gives a more complete picture of material performance.

Real-World Confidence Through Testing

Mechanical testing results have very practical implications. If a batch of alloy steel shafts passes all the tests, you gain confidence those shafts won’t unexpectedly snap or deform in the field. For example, a tensile test might confirm the yield strength of a steel meets the required 60,000 psi minimum, so it won’t permanently bend under normal loads. An impact test at low temperature might show the steel can absorb, say, 50 J of energy without fracture, indicating it won’t shatter if there’s a sudden shock or if the temperature drops. Hardness tests might reveal that the shaft surface is hardened to, say, 55 HRC, implying excellent wear resistance against friction. By contrast, if any result falls short – perhaps the Charpy test absorbed energy is too low – it’s a red flag that the material could be unsafe in service (e.g. risk of brittle fracture in cold conditions). In such cases, re-engineering or using a different alloy may be necessary. Thus, mechanical testing is not just an academic exercise; it directly prevents failures and saves lives and money by catching weaknesses before parts are put into operation.

WH Labs – Your Trusted Mechanical Testing Partner

When it comes to mechanical testing, WH Labs stands out as the best and most trusted facility for several reasons. First, our lab is fully accredited (ISO 17025 and NADCAP certifications, among others), which means all our test methods and calibrations meet rigorous quality standards. You can trust that the data we provide is accurate and reliable. Our lab is equipped with cutting-edge testing machinery, including modern Instron universal testing machines for tensile and bend tests, pendulum impact testers that are routinely calibrated with NIST-traceable standards, and a suite of hardness testers for every scale (Rockwell, Brinell, Vickers, etc.). This advanced equipment allows us to test materials from high-strength steels and alloys to softer metals and even plastics with equal precision.

Secondly, our team of experienced engineers and technicians brings deep expertise in materials science and test protocols. They not only conduct tests meticulously but also interpret the results to give clients actionable insights. For example, if a tested sample failed below specification, our experts can analyze the stress-strain curve or fracture surface to suggest whether a material defect or improper heat treatment was the culprit. This consultative approach sets WH Labs apart – we don’t just hand you numbers, we help you understand what they mean for your project’s success.

Furthermore, we pride ourselves on excellent client service: quick turnaround times, clear and detailed reports, and the flexibility to accommodate special testing needs. Need a custom fixture for an unusual component tensile test? Or on-site hardness testing at your facility? We can handle it. Our Houston-based laboratory has supported clients in oil & gas, aerospace, construction, and manufacturing for over 30 years, earning their trust through consistent quality. We adhere to internationally recognized testing standards (ASTM, ISO, etc.), so the results can be used for code compliance, material certifications, and engineering design with confidence.

Takeaway

Mechanical testing is your assurance that a metal part will perform as expected when faced with heavy loads, bending forces, or sudden impacts. It’s a critical step in quality control and safety verification for any engineered product. By leveraging WH Labs’ comprehensive mechanical testing capabilities, you ensure that no material weakness goes unnoticed. Our facility’s unparalleled expertise and commitment to accuracy make us the ideal partner to verify the strength and toughness of your materials. When we certify that your metal parts passed our tests, you can proceed knowing they are truly ready to withstand the stresses of real-world operation.