Inter Granular Corrosion Test: Evaluation and Prevention

The Intergranular Corrosion Test assesses a material’s susceptibility to corrosion along its grain boundaries. This test involves immersing the material in a corrosive solution, such as nitric acid for stainless steel, and examining for signs of intergranular attack. It is crucial in evaluating the integrity of materials used in critical applications, such as petrochemical equipment or aerospace components.

What is an Inter Granular Corrosion Test?

An intergranular corrosion test is like a health check-up for metal alloys, especially stainless steels. It helps us understand vulnerability to a specific type of corrosion that eats away at the grain boundaries, which are like the seams that hold the metal together.

Picture this: If you have a brick wall, the grains of the metal are like the bricks, and the cement between them is the grain boundaries. Now, if something is eating away at the cement, pretty soon your wall might start falling apart. In a similar way, when corrosion starts happening along these grain boundaries in metals, it can weaken their entire structure.

The stunning thing is that this kind of corrosion can happen without anyone even noticing. The metal looks perfectly fine on the outside while slowly crumbling from within. An intergranular corrosion test is crucial to find out if there’s any hidden damage that could affect the safety and reliability of the material.

Why Does This Matter?

An intergranular corrosion test matters a lot, especially in industries where safety and reliability are non-negotiable. For instance, in airplanes, stainless steel alloys are often used to make components like fuel tanks and hydraulic lines. Imagine what would happen if these materials started corroding from within due to intergranular corrosion! It’s easy to see why testing for this type of corrosion is so critical in ensuring passenger safety.

Aim of Conducting an Inter Granular Corrosion Test

When discussing conducting an inter granular corrosion (IGC) test, it’s not just a routine check. There’s a deeper purpose behind this meticulous examination. The primary goal lies in understanding the reactivity of metal alloys within their grain boundaries—an essential aspect that influences their overall performance and durability.

Metal alloys that are sensitized become vulnerable to grain boundary corrosion, which can eventually lead to structural failure. By conducting an IGC test, we aim to gauge the degree of sensitization in these materials. This provides a clear indicator of how susceptible the alloy is to inter granular attack, aiding in the assessment of its ability to withstand corrosive environments.

This comprehensive evaluation is critical for determining whether a specific material is suitable for use in industries such as chemical processing plants or marine structures, where exposure to harsh and corrosive surroundings is inevitable.

In essence, the aim of conducting an inter granular corrosion test can be summarized as follows:

- Assessing Sensitization: The primary objective is to evaluate the degree of sensitization in metal alloys.

- Determining Resistance: This test helps measure the material’s resistance to inter granular attack.

- Applicability in Corrosive Environments: It is vital for determining the suitability of metal alloys for use in settings exposed to corrosive elements.

By keeping these aims in mind and meticulously conducting the inter granular corrosion test, valuable insights into the integrity and reliability of metal alloys are gained, paving the way for informed decisions regarding their application in various industrial environments.

Techniques for Performing an Inter Granular Corrosion Test

When it comes to evaluating the intergranular corrosion susceptibility of stainless steel, several standardized and widely practiced methods are available. Let’s explore two well-known tests: the Huey Test and the Strauss Test.

The Huey Test

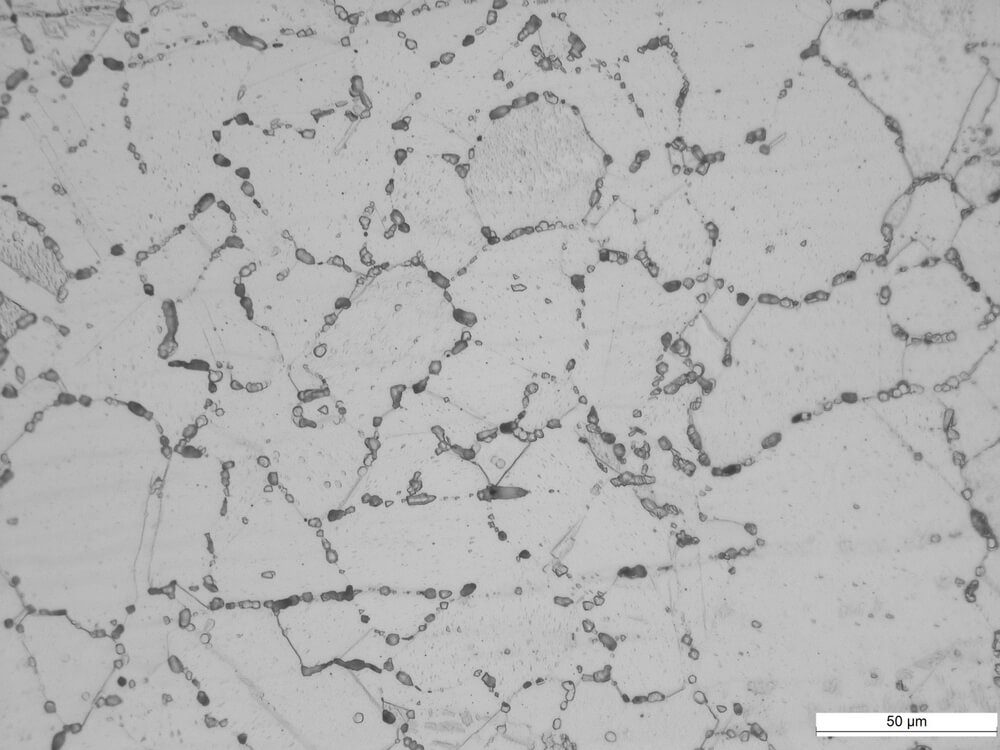

The Huey test is a method used to evaluate the degree of sensitization in stainless steel, specifically referring to the precipitation of chromium carbides at the grain boundaries due to exposure to high temperatures. To conduct this test, a specimen of the stainless steel is immersed in a solution of nitric acid and then subjected to boiling water. The aggressive conditions, including boiling in nitric acid along with elevated temperatures, accelerate the formation of chromium carbides along the grain boundaries. This process reveals any sensitization present in the steel by causing chromium carbides to form along the grain boundaries where they are visible under a microscope.

By conducting this test, we can determine if the material is prone to intergranular corrosion due to sensitization. If carbides form along the grain boundaries, it indicates that the material is susceptible to intergranular corrosion. This test is crucial for identifying whether sensitization is occurring in stainless steel and can help predict how it might behave in real-world applications.

The Strauss Test

The Strauss test, also known as the ASTM A262 Practice E test, is another method used to evaluate the susceptibility of stainless steels to intergranular corrosion. This test involves immersing a polished metal sheet in a boiling 67% solution of copper sulfate and 33% sulfuric acid for a specified period. This harsh environment accelerates the formation of intermetallic phases along the grain boundaries, making them easier to detect.

This process allows us to assess whether there is any loss of corrosion resistance due to intergranular attack. If intermetallic phases are found along the grain boundaries after this test, it indicates that the material is susceptible to intergranular corrosion. Identifying such susceptibility early can help take preventive measures and select suitable materials for specific applications.

Both these tests allow us to evaluate the behavior of stainless steel in critical environments where issues related to sensitization and intergranular corrosion could occur.

Selecting Appropriate Specimens for Testing

In the realm of materials like stainless steel, not every piece is created equal. Different parts of the same piece might behave differently when exposed to corrosion. Therefore, choosing the right specimens for testing is crucial in obtaining accurate insights into the material’s behavior.

One crucial aspect is to ensure that the specimens mirror the actual conditions in which the stainless steel will be used. If the steel will be exposed to a specific environment or certain stress conditions, the test specimens should reflect these factors as closely as possible. This ensures that the test results provide practical data, guiding decision-making processes.

Moreover, it’s important to pay attention to the form of the specimens. Small coupons or plates with standardized dimensions are typically utilized for consistency across the testing process. The size, shape, and surface finish of these specimens are carefully considered to eliminate any variables that could impact the accuracy of the test results.

For instance, if a particular grade of stainless steel is primarily used in thin sheets in its intended application, then the test specimens should mimic this profile as closely as possible. This may involve precise cutting techniques to create thin samples that match the real-world use case.

Ensuring Precision in Sample Preparation

In our laboratory, we adhere to strict guidelines for sample preparation, ensuring that each specimen is meticulously crafted to maintain accuracy in the results. By utilizing advanced cutting and polishing techniques, we guarantee that the specimens are representative of their intended applications. This meticulous approach allows us to provide our clients with precise data for making informed decisions regarding their materials.

The use of precise sample preparation techniques also enables us to minimize external influences on the test results. By carefully controlling variables such as surface finish and geometry, we can isolate the impact of intergranular corrosion on the material, leading to more meaningful and actionable findings.

Selecting appropriate specimens for testing is a critical step in ensuring that the intergranular corrosion test provides valuable insights into the behavior of stainless steel in specific environments and applications. Our commitment to precision in sample preparation underscores our dedication to delivering accurate and reliable results for our clients.

With meticulous care taken in selecting and preparing specimens, we now turn our attention towards understanding the observation parameters crucial for an effective intergranular corrosion test.

Observation Parameters

When conducting the intergranular corrosion test, closely observing and measuring the extent of grain boundary corrosion is crucial. This involves evaluating the depth of attack and the affected area to determine the material’s susceptibility to intergranular corrosion.

Expanding on the idea, observing the depth of attack is essential for identifying how deeply the corrosion has penetrated the material. Engineers and technicians can determine the severity of the corrosion and how it may impact the structural integrity of the stainless steel by measuring this depth. It plays a vital role in understanding the material’s susceptibility to this type of corrosion.

Additionally, evaluating the affected area provides insight into how widespread the corrosion is within the material. This observation helps in determining whether the corrosion is localized or if it has spread extensively throughout the grain boundaries, which can significantly compromise the material’s properties.

For instance, if only a small area of the material is affected, it may indicate that certain environmental factors or specific sensitization processes are causing localized corrosion. On the other hand, if a larger area is affected, it could signal a more widespread susceptibility to intergranular corrosion, possibly due to inherent material issues.

Furthermore, these observation parameters play a critical role in understanding how different alloys and heat treatments influence susceptibility to intergranular corrosion. By recording and analyzing these parameters across various materials and processing methods, researchers and materials scientists can develop a deeper understanding of how to mitigate intergranular corrosion through appropriate alloy selection and heat treatment processes.

Understanding these observation parameters enhances our ability to assess and address intergranular corrosion effectively in stainless steel materials. Now, let’s explore various prevention methods that leverage knowledge to ensure long-term material integrity.

Determining Corrosion Resistance Properties

When we discuss determining the corrosion resistance properties of stainless steel, we’re essentially examining how well the material holds up against rust and other forms of corrosion. This is a crucial part of ensuring that the material is suitable for various applications, particularly in industries where safety and reliability are paramount.

The test results from evaluating intergranular corrosion provide valuable insights that guide material selection and engineering practices. These insights are critical because they influence key decisions regarding which materials are best suited for specific engineering and industrial applications. For instance, in the chemical industry, where exposure to harsh chemicals is common, selecting materials with high corrosion resistance is imperative. Similarly, in the medical and food processing sectors, where hygiene and purity are paramount, choosing materials that resist corrosion effectively is essential.

Take the medical industry; in medical device manufacturing, implantable devices made from stainless steel must endure the body’s natural salts and bodily fluids without corroding. Failure to select a highly resistant stainless steel alloy can lead to device deterioration and potential harm to patients.

By evaluating a material’s performance under corrosive environments, we can make informed decisions about its suitability for specific applications, significantly contributing to ensuring safety and reliability across various industries.

“Within certain settings, like marine environments or chemical processing plants, the environment can be particularly aggressive on metal equipment and structures. Hence, thorough corrosion resistance testing becomes even more critical in these scenarios.”

Additionally, having comprehensive information about a material’s corrosion resistance allows us to predict its service life accurately. It enables us to assess whether a specific stainless steel alloy will withstand the conditions it will be exposed to over time.

Evaluating a material’s corrosion resistance properties provides key data that informs our material selection processes, guides our engineering decisions, and ensures the safety and reliability of numerous industry applications.

Practical Advantages of the Test

Our findings from the test underscore the highly advantageous nature of identifying materials prone to intergranular corrosion. Understanding which alloys are susceptible to this type of corrosion allows for the selection of appropriate materials for specific applications, thereby directly aiding in preventing costly failures and ensuring the longevity of structures or components made from stainless steel. Being unaware of these vulnerabilities could lead to severe problems down the line, such as material failure, costing time and resources in the long run.

Moreover, conducting intergranular corrosion tests plays an integral role in quality assurance. It allows us to identify and mitigate corrosion vulnerabilities before the material is put into service, preventing potential issues from arising and thus maintaining the integrity and reliability of the materials we employ.

Engaging in forward-thinking quality control by conducting these tests ensures that our materials are not only resistant to corrosion but are also fit for their intended purpose. Consequently, these assessments significantly contribute to ensuring the safety and reliability of structures and components made from stainless steel.

While taking these measures may seem time-consuming initially, they ultimately save both time and resources by preventing future complications. Thus, our commitment to thorough testing enables us to uphold industry standards and deliver products that you can trust.

In our quest to understand and combat intergranular corrosion, prevention plays a crucial role. Let’s now explore effective methods against intergranular corrosion, fortifying our understanding of this persistent threat.

Prevention Methods against Inter Granular Corrosion

Stainless steel is a remarkable material, but it’s not invincible. To prevent intergranular corrosion, proper heat treatment is crucial. This involves heating the metal to a specific temperature and then letting it cool slowly, which helps rearrange the atoms within the metal, making it less susceptible to corrosion along the grain boundaries.

Furthermore, alloy modification can significantly enhance the resistance of stainless steel to intergranular corrosion. By carefully adjusting the composition of the alloy, particularly reducing the carbon content, manufacturers can create a stainless steel variant that is more resistant to this type of corrosion.

In addition, the use of corrosion-resistant coatings is a vital preventive measure. Coatings such as epoxy, polyurethane, or fusion-bonded epoxy coatings act as a protective barrier between the metal surface and the external environment, minimizing exposure to corrosive elements.

Our laboratory at W H Laboratories provides expert guidance on implementing these preventive measures based on the results obtained from intergranular corrosion testing. We offer comprehensive insights and consultations to help industries select the most suitable prevention methods based on their specific requirements and the properties of the metal being used in their applications.

By adopting these preventive measures and leveraging expert guidance from our laboratory, industries can effectively mitigate intergranular corrosion, ensuring the longevity and reliability of their metal components in diverse industrial settings.

Implementation of these prevention methods can significantly minimize the risk of intergranular corrosion in stainless steel, thereby ensuring the durability and functionality of metal components across various industries.