How Magnetic Particle Testing Helps Catch Surface Cracks

Let’s investigate how magnetic particle testing (MPT) detects critical failures within essential industries. MPT functions as an essential early warning system because it detects tiny surface cracks before they transform into major structural problems. The diagnostic power of this method stems from basic magnetic principles which produce results that surpass other testing methods. The unique features of this testing method enhance its effectiveness so much that industries which cannot afford any failure point to it as their essential diagnostic tool.

Key Points

MPT systems identify small cracks on surfaces which prevent their growth into substantial structural damage or component failures. The inspection method shows hidden defects at depths of 0.25 inches which could lead to essential structural failure. Under suitable illumination the magnetic particles show at crack sites to reveal what was invisible before. MPT inspection carried out regularly builds a record of defects which helps engineers predict failure patterns in essential equipment. The quick results enable swift choices regarding maintenance before minor cracks advance to disastrous states.

The Science Behind Magnetic Particle Inspection Requires Explanation

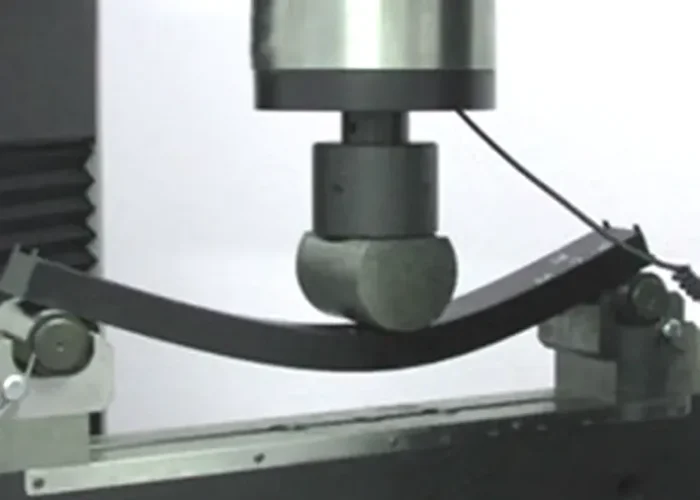

The inspection begins with applying fine ferromagnetic particles through dry iron powder or liquid-based suspensions to the specimen surface. The natural magnetic attraction of the particles leads them to cluster at defective areas which form detectable indications.

The method operates according to simple physical principles since defects between north and south poles cause particles to gather at edges while producing recognizable patterns that expose invisible defects. The basic principle enables us to detect surface and near-surface flaws with outstanding precision.

The inspection method brings significant value to a comprehensive NDT approach that maintains structural integrity of critical infrastructure components including aerospace parts and oil pipelines.

Common Applications and Industries Relying on MPT

Among various NDT inspection protocols today Magnetic Particle Testing (MPT) stands as an essential method which serves multiple critical industrial sectors.

Magnetic Particle Testing stands tall among NDT methods, proving irreplaceable across industries where component integrity means everything.

MPT has become a standard inspection method across aerospace and automotive manufacturing and oil and gas and power generation sectors because ferromagnetic component failure represents an unacceptable risk.

The inspection of landing gear as well as turbine components and critical structural elements depends on MPT in aerospace engineering applications.

Automotive manufacturers use MPT for testing engine components, crankshafts, and suspension parts

MPT serves pipeline operators for weld verification and corrosion assessment purposes.

The testing requirements of MPT extend to turbine shafts and generators in power generation facilities.

The military sector along with defense contractors apply MPT for both weapons system inspections and vehicle inspections.

MPT demonstrates its effectiveness by detecting fatal flaws in high-consequence industries through its ability to inspect various sectors.

MPT detects surface and subsurface discontinuities in ferromagnetic materials which makes it crucial for discovering potential structural weaknesses early.

A Systematic Approach Is Necessary for Running an Effective Testing Process

Magnetic Particle Testing needs a structured procedure to ensure dependable defect identification across industries including those previously discussed.

The test component requires thorough cleaning to eliminate contaminants which might obscure defects. A surface defect requires alternating current for magnetization but direct current works for subsurface defect detection.

The inspection process includes applying ferromagnetic particles which exist either as dry powder or wet suspension to find magnetic flux leakages at discontinuities.

We look at the part under suitable lighting conditions following particle settlement at defects including white light for regular particles and UV light for fluorescent ones.

We’ll document all findings meticulously. The demagnetization process of the component is performed to remove any remaining magnetism which would interfere with operational activities or attract foreign particles.

Our attention to proper procedures during each step prevents essential flaws from going unnoticed.

We enhance accuracy by using either wet and dry fluorescent magnetic particle testing methods based on the part geometry and inspection needs.

Advantages Over Other Non-Destructive Testing Methods

Magnetic Particle Testing (MPT) proves superior to alternative non-destructive testing methods because of its unique advantages which make it suitable for specific inspection needs.

We have established that MPT outperforms all other methods in detecting ferromagnetic material surface and near-surface flaws.

The surface and near-surface defects that visual inspection cannot detect are revealed by MPT in ferromagnetic materials.

- MPT detects defects on the surface and in shallow subsurface regions which visual inspection fails to identify.

- The method requires less surface treatment compared to penetrant testing techniques.

The results from MPT are immediate since they do not require the processing delays of radiographic testing methods.

The cost of MPT equipment stands significantly lower than that of ultrasonic or eddy current testing equipment.

- MPT works successfully on geometrically complex parts that other testing approaches encounter difficulties with.

The advantages of MPT make it our top choice for safety-critical aerospace and automotive and structural applications which use ferromagnetic materials.

The accurate interpretation of iron particle patterns depends on proper certifications and skills as explained by certifications and skills.

Case Studies: When Early Detection Prevented Major Failures

The effectiveness of Magnetic Particle Testing becomes evident through real-world applications which identify serious defects before failure happens.

Our 2019 maintenance inspection revealed hairline cracks in a steel bridge support beam that prevented a catastrophic structural collapse which could have harmed hundreds of people.

The inspection of a power plant turbine shaft revealed subsurface fatigue cracks which were invisible to visual inspection thus allowing replacement before catastrophic failure.

The aerospace industry has identified tiny stress cracks in landing gear components that survived numerous load cycles.

Our testing in the automotive sector verifies crankshaft integrity while we detect stress concentrations in crucial areas during manufacturing quality control.

Our ability to identify issues at an early stage produces minimal remediation expenses when compared to failure-related costs. The non-destructive testing method of magnetic particle testing does not have the same capability as ultrasonic techniques to detect internal defects within materials without inflicting any damage to the tested components.

Frequently Asked Questions

What Environmental Factors Can Affect MPT Accuracy?

The accuracy and reliability of our magnetic particle testing methods suffers from temperature extremes, moisture, dust, electromagnetic interference, surface coatings and improper lighting conditions.

What is the recommended frequency for calibrating MPT equipment?

We conduct annual equipment calibration for MPT but critical applications need semi-annual verification. The first testing step requires daily operational checks. The precise calibration intervals should follow the standards defined in ASTM E1444 while performing MPT. Always.

Can MPT Be Performed on Non-Ferrous Materials?

Magnetic particle testing (MPT) cannot function on non-ferrous materials because it requires ferromagnetic properties to work properly. The inspection of aluminum, copper and austenitic stainless steels requires penetrant testing since MPT is not applicable.

What Qualifications Are Required for MPT Technicians?

MPT technicians need to achieve Level I, II or III certification from SNT-TC-1A or NAS-410 standards and complete NDT training and understand ferromagnetic theory and demonstrate inspection equipment proficiency.

How Are Test Results Documented and Retained for Compliance Purposes?

We document MPT results using detailed inspection reports, photographs, and digital records. Our team will keep these files in accordance with industry standards and regulatory requirements to maintain traceability and quality management system compliance.

Takeaway

This paper shows magnetic particle testing allows for the detection of surface discontinuities through ferromagnetic principles at an early stage. Our strict MPT protocols enable the discovery of potential failure points which will prevent major problems from occurring. Our analysis shows that MPT offers better detection of hairline cracks in ferromagnetic materials than other NDT methods. The documented case studies demonstrate the essential function of MPT in maintaining structural integrity for various high-risk industrial sectors.