How Failure Analysis Saves You Time and Money

We’ve all experienced that sinking feeling when equipment fails at the worst possible moment. What if those breakdowns could actually save your organization money? In our analysis of industrial maintenance practices, we’ve found that systematic failure analysis transforms problems into valuable knowledge assets. By understanding exactly why components fail, companies reduce repeat issues by up to 60% and extend equipment lifecycles substantially. The financial implications might surprise you.

Key Points

- Petroleum refineries implementing failure analysis reduce unplanned downtime by 37% and save $4.2 million annually.

- Structured failure analysis protocols help companies achieve 25-40% reductions in maintenance costs.

- Root cause analysis prevents wasteful repair cycles by identifying and addressing the true source of failures.

- Documented investigations create knowledge repositories that prevent repeated failures and accelerate future troubleshooting.

- Statistical modeling of failure data predicts component life expectancy, enabling proactive maintenance before costly breakdowns occur.

The Hidden Costs of Equipment Failure Beyond Repairs

When equipment fails unexpectedly in industrial settings, the immediate repair costs represent only the tip of the financial iceberg. We often overlook the cascading financial impacts that follow mechanical breakdowns.

Production downtime translates directly to missed orders and revenue loss. Our team members face idle time, yet we still pay their wages. Customer relationships suffer when we can’t deliver on promises, potentially costing us future business. We’ll likely incur rush fees for expedited parts and emergency service calls.

Quality issues may emerge as we rush to resume operations, leading to more scrap and rework. Safety risks increase when we’re operating under pressure, potentially resulting in injuries and their associated costs. These hidden expenses typically amount to 4-15 times the visible repair costs, making a compelling case for investing in proper failure analysis.

Implementing preventive measures developed through comprehensive failure analysis can significantly reduce unplanned shutdowns and their associated financial impact.

Understanding Root Cause Analysis vs. Quick Fixes

Although quick fixes may temporarily restore equipment function, they rarely address the underlying problems that caused the failure in the first place.

We often fall into this trap when facing production pressures, opting for band-aid solutions that keep operations moving but set us up for repeated failures.

Root cause analysis, in contrast, involves systematically investigating the failure to identify its fundamental origin.

We use techniques like the “5 Whys” or Ishikawa diagrams to trace failure pathways back to their source.

While this approach requires more initial investment of time and resources, it prevents recurrence of the same failure mode, ultimately saving us substantial money and downtime.

When we commit to thorough failure analysis, we’re not just fixing today’s problem—we’re protecting tomorrow’s productivity.

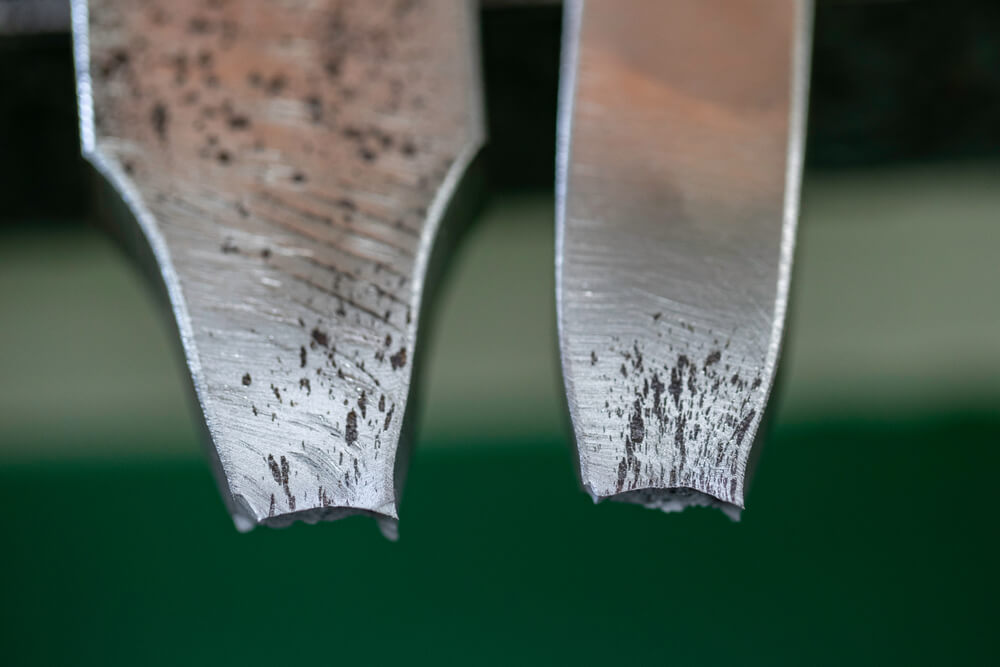

Advanced metallurgical testing techniques provide critical insights into material properties that often reveal hidden failure mechanisms invisible to the naked eye.

Five Ways Failure Analysis Extends Asset Lifespan

We’ve identified five critical ways failure analysis contributes to extending asset lifespan, beginning with root cause detection that addresses underlying issues rather than symptoms.

Our maintenance optimization insights derived from failure data enable teams to schedule preventive interventions at ideal intervals, eliminating both excessive and insufficient maintenance activities.

Through systematic lifecycle risk mapping, we can predict failure points across an asset’s operational timeline, allowing for strategic reinforcement of vulnerable components before catastrophic failures occur.

Our comprehensive approach includes non-destructive testing techniques to evaluate material integrity without causing any damage to the assets being examined.

Root Cause Detection

Root cause detection forms the cornerstone of effective failure analysis, enabling organizations to identify the fundamental issues behind asset breakdowns rather than merely addressing symptoms.

When we dig deeper than surface-level problems, we’re able to prevent recurrence and eliminate wasteful repair cycles.

We use structured methodologies like the 5-Whys technique, fishbone diagrams, and fault tree analysis to systematically trace failures to their origins.

This process reveals hidden connections between seemingly unrelated factors—material defects, design flaws, operational errors, or environmental conditions.

Maintenance Optimization Insights

Failure analysis yields invaluable maintenance optimization insights that directly impact an organization’s bottom line and operational efficiency.

By systematically examining breakdown patterns, we’re able to refine maintenance schedules based on actual performance data rather than manufacturer recommendations alone.

We’ve found that proper failure analysis helps organizations:

- Identify ideal maintenance intervals that prevent costly emergency repairs

- Prioritize critical components that warrant condition monitoring

- Develop targeted inspection protocols for vulnerable system areas

- Create equipment-specific lubrication schedules that extend component life

- Implement strategic parts inventory management based on failure frequency

These insights don’t just prevent failures—they transform reactive maintenance cultures into proactive ones.

When we optimize maintenance through failure analysis, we’re not just fixing problems; we’re systematically extending asset lifespan while reducing overall maintenance costs.

Lifecycle Risk Mapping

Through thorough lifecycle risk mapping, organizations can systematically identify and mitigate potential failure points at every stage of an asset’s operational life.

We’ve found that by incorporating thorough risk assessment at installation, mid-life, and end-of-life stages, we’re able to predict when failures are most likely to occur.

Our approach typically includes:

- Timeline Visualization – Creating graphical representations that map specific risks to operational timeframes, highlighting vulnerability windows

- Conditional Probability Analysis – Calculating failure likelihood based on asset age and operational stress

- Intervention Point Identification – Determining ideal timing for preventive maintenance or replacement

When we implement structured lifecycle risk mapping, we’re not just documenting potential failures—we’re creating a shared language of risk awareness that brings maintenance teams, operators, and management into alignment around critical asset protection strategies.

Transforming Breakdowns Into Valuable Data Points

When equipment breakdowns occur, they present more than just operational setbacks—they offer critical data points that can transform our understanding of systemic vulnerabilities.

Each failure contains information about design weaknesses, usage patterns, and component lifespan that we can’t obtain through normal operations.

We’ve developed methodologies to systematically collect this data.

When your equipment fails, we document specific failure modes, environmental conditions, maintenance history, and operator feedback.

This creates a feedback loop where breakdowns directly inform design improvements and preventive measures.

Through comprehensive root causes analysis, we provide crucial insights that help prevent recurring equipment failures while enhancing overall reliability.

Building a Predictive Maintenance Strategy From Failure Patterns

Once isolated incidents are compiled into an exhaustive database, patterns of equipment failure begin to emerge that enable us to develop targeted predictive maintenance strategies.

We’re no longer reacting to breakdowns—we’re preventing them before they impact our operations and bottom line.

Our team transforms these failure patterns into actionable maintenance protocols through:

- Failure mode classification – Categorizing breakdowns by mechanism, frequency, and impact to prioritize intervention

- Statistical modeling – Applying Weibull analysis and machine learning to predict component life expectancy

- Threshold establishment – Setting clear indicators that trigger maintenance actions before critical failure occurs

Incorporating metallurgical testing methods into our predictive maintenance strategy provides crucial insights about material behavior under stress and in different operating environments.

Real-World Success Stories: ROI of Systematic Failure Analysis

While theoretical frameworks for failure analysis provide valuable foundations, the true evidence to their effectiveness lies in quantifiable results.

We’ve documented numerous success stories across industries that demonstrate compelling ROI.

A petroleum refinery implemented our systematic analysis approach and reduced unplanned downtime by 37%, saving $4.2 million annually.

Similarly, a medical device manufacturer cut failure-related costs by 62% and accelerated product development cycles by eight weeks.

These aren’t isolated cases.

These data points represent a consistent pattern of success across diverse industries and applications.

Companies consistently report 25-40% reductions in maintenance costs when adopting structured failure analysis protocols.

Beyond immediate savings, we’re seeing long-term benefits in improved product reliability and extended equipment lifecycles.

The data confirms what we’ve long believed: investing in understanding why things fail pays dividends throughout the entire operational lifecycle.

When we learn from failures systematically, we transform expensive problems into valuable organizational knowledge.

Implementing comprehensive material testing services across critical applications significantly reduces the risk of catastrophic failures while ensuring compliance with industry standards.

Implementing a Failure Analysis Program in Your Organization

We’ll substantially enhance our failure analysis outcomes by establishing clear investigation protocols that define triggers, responsibilities, and resolution pathways.

Training cross-functional teams creates a collaborative environment where diverse expertise converges to identify both obvious and subtle failure mechanisms.

Documenting every investigation thoroughly—from initial observations to root cause determinations and corrective actions—builds an invaluable knowledge repository that prevents repeated failures and accelerates future troubleshooting.

Incorporating metallography testing techniques into your analysis program provides crucial insights into material microstructure that can reveal the root causes of component failures and prevent costly breakdowns.

Establish Clear Investigation Protocols

When implementing a failure analysis program, establishing clear investigation protocols serves as the cornerstone of effective troubleshooting operations.

These protocols guarantee that our teams follow consistent, repeatable procedures when analyzing failures, leading to more reliable results and actionable insights.

We’ve found that exhaustive protocols should include:

- Defined roles and responsibilities for each team member involved in the investigation process

- Specific documentation requirements, including initial observations, testing methods, and analytical results

- Decision trees that guide investigators through the analysis process based on failure characteristics

Train Cross-Functional Teams

Building a robust failure analysis program requires cross-functional team training that breaks down traditional departmental silos. We’ve found that when engineers, quality specialists, production staff, and customer service representatives collaborate, failure patterns become more apparent.

Training should focus on both technical analysis methods and communication protocols. We recommend starting with fundamentals like root cause analysis, statistical tools, and investigation techniques that everyone can apply, regardless of their primary discipline.

Our most successful clients implement regular simulation exercises where team members practice working through real-world failure scenarios together. This builds analytical muscle memory while fostering mutual respect for different perspectives.

Document Everything Thoroughly

Documentation serves as the backbone of any effective failure analysis program, providing both historical reference and actionable intelligence for future improvements.

When we document thoroughly, we create a knowledge base that helps us identify patterns and prevent recurring issues.

This practice transforms individual experiences into organizational wisdom.

To implement effective documentation:

- Capture timing, conditions, and symptoms – Record when the failure occurred, environmental factors present, and all observable manifestations of the problem

- Include imagery and data – Attach photographs, videos, sensor readings, and test results that provide objective evidence

- Document resolution steps – Detail all attempted fixes, their outcomes, and the final solution that restored functionality

This level of documentation converts our failures into valuable learning opportunities that ultimately strengthen our processes and save significant resources.

Frequently Asked Questions

How Quickly Can Failure Analysis Provide Actionable Results?

We can deliver actionable failure analysis results within hours for urgent cases, while complex investigations typically take 1-2 weeks as we methodically evaluate evidence and identify root causes.

What Qualifications Should Failure Analysis Personnel Have?

We look for failure analysts with engineering degrees, industry certifications, and extensive materials science knowledge. They’ll need problem-solving abilities, systematic thinking, technical writing skills, and experience with advanced analytical equipment.

Can Failure Analysis Be Outsourced or Must It Be In-House?

We can outsource failure analysis successfully when needing specialized expertise or equipment, though in-house options provide greater control and institutional knowledge retention. Both approaches offer distinct advantages worth considering.

How Does Failure Analysis Apply to Software Systems?

In software systems, we analyze defects by examining code, logs, and performance data. We’ll identify root causes through systematic debugging, trace error sequences, and implement targeted fixes to prevent recurrence.

What’s the Minimum Equipment Investment Needed for Basic Failure Analysis?

We’ll need minimal equipment for basic failure analysis: a good microscope ($200-500), digital camera, precision tools, and analytical software. Our community typically starts with these essentials before expanding capabilities.

Takeaway

By implementing systematic failure analysis, we’ve shown how equipment breakdowns transform from costly disruptions into strategic opportunities. We’re not just fixing problems—we’re creating predictable maintenance cycles, extending asset lifespans, and capturing measurable ROI. The data patterns we’ve identified enable us to prevent future failures before they occur. Our structured approach doesn’t just save money; it converts failures into valuable organizational intelligence that drives continuous improvement.