Extend the Life of High-Value Equipment With Precision Clad Welding

In today’s industrial landscape, we’re seeing equipment replacement costs soar while maintenance budgets tighten. Precision clad welding offers a strategic solution by depositing wear-resistant alloys onto critical components, effectively creating a metallurgical shield against corrosion, abrasion, and high-temperature degradation. We’ve documented cases where this technique extended equipment life by 300-400% compared to untreated parts. The science behind this remarkable longevity involves careful control of dilution zones—but that’s just the beginning of what makes this process so valuable.

Key Points

- Precision clad welding creates a metallurgical bond that protects equipment from corrosion, abrasion, and chemical attack in harsh environments.

- Controlled dilution zones (under 10%) ensure optimal material properties at the interface between base metal and protective overlay.

- Targeted cladding repairs offer 30-70% cost savings compared to complete component replacement while maintaining performance standards.

- Regular monitoring with ultrasonic thickness testing identifies wear points early, enabling strategic intervention before critical failure occurs.

- ASME-certified welding procedures guarantee compliance with industry regulations while extending equipment service life in oil, mining, and power sectors.

Understanding the Science Behind Precision Clad Welding

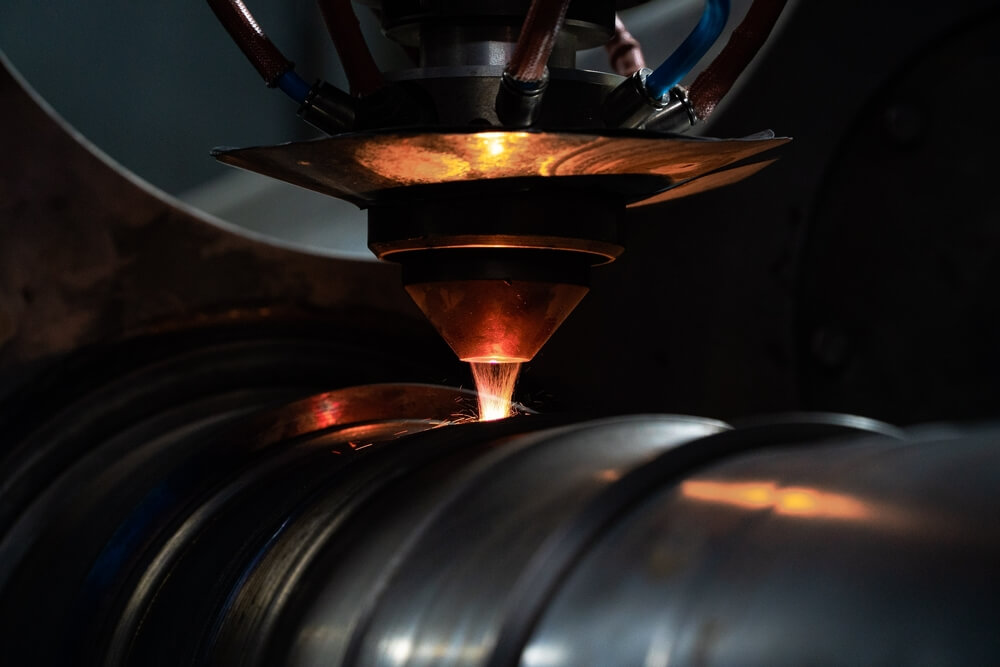

When examining the fundamental principles of precision clad welding, we must first understand the metallurgical interactions that occur at the interface between dissimilar materials. These interactions create a metallurgical bond rather than merely a mechanical one, resulting in superior adhesion and performance.

We’re creating a protective layer of material with specific properties—corrosion resistance, wear resistance, or heat tolerance—over a base material that provides structural integrity. The key to success lies in controlling the dilution zone where these materials mix, typically keeping it under 10%.

Our process employs precise heat input control, specialized filler materials, and calculated deposition rates to minimize residual stress and prevent defects like cracking or delamination. Professional overlay welding services often include non-destructive testing to verify the integrity of these critical components. By mastering these scientific principles, we’re able to extend equipment life in the harshest industrial environments while maintaining dimensional tolerance and material integrity.

Key Industries Benefiting From Clad Welding Applications

Industries with demanding operational environments consistently drive the innovation and application of precision clad welding technologies.

Harsh operational demands fuel continuous advancement in specialized metallurgical protection solutions across critical industries.

We’ve seen remarkable adoption across oil and gas, where components face corrosive chemicals, high pressures, and abrasive materials that would quickly deteriorate unprotected surfaces.

Mining and mineral processing operations benefit similarly, as equipment handling abrasive ores and slurries requires exceptional wear resistance.

In power generation, we apply cladding to boilers, heat exchangers, and turbine components to withstand extreme temperatures and steam erosion.

Chemical processing plants rely on our clad solutions to protect vessels and piping systems from aggressive chemicals.

The maritime industry also depends on cladding for propeller shafts and shipbuilding components exposed to seawater corrosion.

These critical industries share our commitment to extending equipment life through precision metallurgy.

White House Laboratories in Houston provides custom overlay solutions tailored to each industry’s specific requirements and operational challenges.

Cost-Benefit Analysis: Why Clad Welding Outperforms Replacement

Although initial investment in clad welding technologies appears substantial, our thorough cost analyses consistently demonstrate superior long-term economic benefits compared to component replacement strategies.

We’ve documented average savings of 30-70% when implementing targeted clad repair versus complete component replacement.

These economic advantages stem from multiple factors: substantially reduced downtime, minimal material requirements, decreased labor hours, and elimination of requalification procedures for new components.

Additionally, we’ve tracked extended service intervals following precision cladding repairs, further enhancing ROI.

When we factor in the operational disruptions of full replacements—production halts, installation complications, and potential cascade failures—the economic equation clearly favors our clad welding approach.

For your critical assets, this translates to preserved capital while maintaining ideal performance and reliability standards.

Our corrosion resistant overlay specialization ensures equipment longevity in even the most challenging industrial environments.

Best Practices for Implementing a Preventative Clad Welding Program

Having established the economic advantages of clad welding, we’ll now outline the systematic approach to developing an effective preventative program.

First, conduct thorough equipment assessment to identify critical wear points and failure-prone components.

Document baseline metal conditions with ultrasonic thickness testing.

Next, develop inspection schedules that align with operational cycles, targeting high-stress periods for monitoring.

We recommend implementing a tiered intervention protocol—addressing minor wear immediately while scheduling thorough treatments during planned downtime.

Train maintenance teams to recognize early wear indicators and document all interventions in a centralized database.

Partner with certified clad welding specialists who understand your industry’s specific challenges.

Finally, establish clear performance metrics to evaluate program effectiveness, including extended equipment life calculations and downtime reduction measurements.

Consider integrating non-destructive testing techniques to detect surface defects and internal irregularities before they develop into critical failures.

Case Studies: Real-World Equipment Life Extension Results

While examining real-world applications of preventative clad welding programs, we’ve documented several remarkable cases that demonstrate quantifiable equipment life extensions.

Our precision cladding interventions consistently yield significant returns on investment across multiple industries.

Consider these documented outcomes:

- A petrochemical facility extended reactor vessel life by 12+ years after implementing our strategic cladding on high-wear zones, avoiding a $3.2M replacement.

- Mining equipment with our proprietary tungsten carbide overlay demonstrated 300% increased service intervals compared to untreated components.

- Power generation boiler tubes with precision cladding at critical erosion points maintained wall thickness within specification for 3 additional operational cycles.

All our welding procedures undergo rigorous ASME certification testing to ensure compliance with industry standards and regulatory requirements.

We’ve found these successes aren’t isolated incidents.

When properly implemented, preventative clad welding consistently delivers measurable life extension while maintaining operational integrity across critical assets.

Frequently Asked Questions

How Long Does a Typical Clad Welding Repair Last?

Clad welding repairs typically last 5-15 years in our experience, though we’ve seen them endure 20+ years with proper application techniques and regular maintenance within industrial service environments.

What Certifications Should Clad Welding Technicians Possess?

Clad welding technicians should possess AWS certifications, ASME qualifications, PQRs, WPSs, and industry-specific endorsements. We’ve found proper documentation of NDT training guarantees our team delivers consistently reliable metallurgical results.

Can Clad Welding Be Performed In-Situ During Active Operations?

We can perform in-situ clad welding during operations in limited scenarios, but safety protocols must address fire risks, ventilation, and equipment isolation to prevent operational disruptions and guarantee personnel protection.

How Does Extreme Temperature Affect Clad Welding Durability?

Extreme temperatures can compromise our clad welding’s durability through thermal expansion stress, microstructural changes, and accelerated oxidation. We’ll need specialized alloy combinations and post-weld heat treatments for reliable high-temperature applications.

Are There Environmental Regulations Specific to Clad Welding Processes?

Yes, we’re subject to EPA and OSHA regulations controlling emissions, fume exposure, and waste disposal. Local jurisdictions may impose additional requirements for particulate matter and heavy metal handling.

Takeaway

We’ve demonstrated how precision clad welding strategically extends equipment service life through controlled dilution zones and specialized filler materials. By implementing this technology with proper pre-weld assessment and post-weld validation, organizations achieve significant ROI through reduced downtime and maintenance costs. Our case studies confirm these applications deliver 2-5× longer component life in corrosive environments. Adopting a systematic clad welding maintenance program isn’t merely preventative—it’s financially imperative for high-value industrial assets.