Mechanical Testing to Ensure Material Strength and Toughness

Mechanical testing is the backbone of verifying that metal parts can withstand real-world stresses. Whether you have a steel beam for construction or a critical turbine component, these tests measure how much load, bending, or impact a material can take before it yields or breaks. At WH Labs, we specialize...

continue reading

Houston Magnetic Particle Testing Lab: Fast, Reliable Results

At WH Labs, we've perfected magnetic particle testing through years of specialized experience in Houston's demanding industrial landscape. Our methodology involves precise surface preparation, controlled magnetization, and strategic particle distribution to identify even microscopic discontinuities. We're committed to delivering results that exceed industry standards while maintaining efficient turnaround times. The...

continue reading

Houston Heights Metallurgical Testing Services

WH Labs provides extensive metallurgical testing services in Houston Heights, TX and all surrounding areas to address the most challenging material characterization needs across industries. Our holistic approach combines microstructural analysis via SEM and X-ray diffraction with rigorous mechanical testing protocols that reveal critical performance parameters. When manufacturing processes fail...

continue reading

Impact Testing Services

We often overlook the durability of materials in our everyday lives, but impact testing plays a significant role in ensuring their reliability. As we explore this essential field of materials science, we'll uncover the various methods used to evaluate a material's ability to withstand sudden forces. From the familiar Charpy test to more advanced techniques, impact testing provides...

continue reading

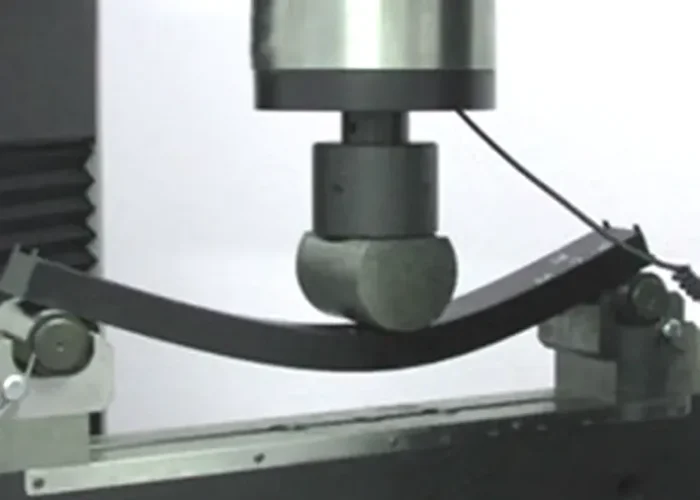

Bend Testing Guide: Techniques, Equipment, and Standards

As we delve into the world of materials testing, we can't overlook the importance of bend testing. It's a vital method that engineers use to assess how materials behave under bending stress. We'll find that this seemingly simple test reveals a wealth of information about a material's ductility, toughness, and overall performance. By understanding...

continue reading

How Does Magnetic Particle Inspection Detect Surface Cracks?

Let's investigate how magnetic particle inspection (MPI) detects critical failures within essential industries. MPT functions as an essential early warning system because it detects tiny surface cracks before they transform into major structural problems. The diagnostic power of this method stems from basic magnetic principles which produce results that surpass...

continue reading

How Failure Analysis Saves You Time and Money

We've all experienced that sinking feeling when equipment fails at the worst possible moment. What if those breakdowns could actually save your organization money? In our analysis of industrial maintenance practices, we've found that systematic failure analysis transforms problems into valuable knowledge assets. By understanding exactly why components fail, companies...

continue reading

Extend the Life of High-Value Equipment With Precision Clad Welding

In today's industrial landscape, we're seeing equipment replacement costs soar while maintenance budgets tighten. Precision clad welding offers a strategic solution by depositing wear-resistant alloys onto critical components, effectively creating a metallurgical shield against corrosion, abrasion, and high-temperature degradation. We've documented cases where this technique extended equipment life by 300-400%...

continue reading

Intergranular Corrosion Testing: WH Labs

WH Labs uses intergranular corrosion testing to assess the vulnerability of materials like stainless steel and nickel-based alloys to corrosion along their grain boundaries. These tests are important for ensuring the safety and reliability of materials in various industries. The Copper Sulfate - Sulfuric Acid Technique and the Huey Test are among the methods used to...

continue reading

Impact Charpy and Izod Testing by WH Labs

In our material testing laboratory, we've observed that impact resilience often reveals critical failure points conventional tensile tests miss. We're continuously analyzing how sudden force application affects various materials under different conditions. The distinction between Charpy and Izod testing methodologies isn't merely procedural—it's fundamental to understanding a material's behavior in...

continue reading

Metals Composition Testing by WH Labs

At WH Labs, we've revolutionized metals composition testing through advanced spectroscopic techniques that detect elements at parts-per-trillion levels. Our ICP-MS, XRF, LIBS, and TXRF methodologies deliver precise results with rapid turnaround times for aerospace, medical, and consumer product applications. We're committed to regulatory compliance with standards like RoHS and REACH...

continue reading

Importance of Working with Accredited and Certified Labs

At WH Labs, we've refined our NDT testing methodologies over decades to detect the smallest flaws that conventional testing might miss. We're constantly upgrading our ultrasonic and radiographic capabilities to meet the evolving demands of aerospace and petrochemical industries. Our ASNT-certified technicians don't just identify defects—they analyze how these imperfections...

continue reading